Clean contact surfaces are vital to ensuring reliable layout operation. George Dent offers some simple tips to help keep your trains moving, and trials a new rail cleaning fluid.

PHOTOGRAPHY: GEORGE DENT

Track-cleaning is a necessary chore for any model railway, even if your layout is kept under dust covers when out of use. Whether it’s generic dust from the railway room or exhibition hall, stray paint deposits, or oil and grease dropped by passing locomotives, our track is inevitably prone to the build-up of unwanted contaminants.

Most track features nickel silver rail, which is naturally prone to tarnishing, while steel rail can corrode if employed in damp locations. The cleanliness (or otherwise) of locomotive and rolling stock wheels can also have a profound effect on the rails. There’s an argument that plastic wheels can lead to dirtier rails, although how true that is, I’m unsure. I do find metal wheels easier to keep clean, however.

Areas of poor contact between the rails and power-collecting metal wheels can lead to the creation of carbon deposits, thus making matters worse. Furthermore, any imperfections in the rail head’s surface will act as a magnet for grime, so it pays to be methodical when cutting and laying track sections in the first instance.

As a child, I recall asking an exhibition layout operator for some track-cleaning tips and, while being temporarily perplexed by the term ‘elbow grease’, soon realised that there were few magic cures, especially as we’re encouraged not to use electronic trackcleaning units these days, due to their incompatibility with DCC and modern motors.

However, time and experience have shown that there are numerous steps a modeller can take to minimise the problem, mostly through adopting a preventative maintenance regime of regular cleaning.

Combining humble track rubbers with cleaning fluids, both of which are available from countless brands, plus a vacuum cleaner and old, clean T-shirts, the job can be achieved with minimum fuss.

One of the latest cleaning products to come my way is a new alcohol-based fluid from Geoscenics. I’ve tested it on a few of my layouts over the past couple of months and found it to be effective for removing general dirt and debris, as well as paint and oily deposits. It’s equally good on rails and metal wheels and hasn’t had any deleterious effects on plastic components or paintwork. It’s certainly ideal for regular use, with a quick wipe down of the rails before each running session helping to ensure smooth running.

STEP BY STEP

1 Rails will always pick up dirt, but we can help minimise deposits by ensuring railheads are as smooth as possible. When cutting and laying track sections, use fine abrasives to polish away any tool marks left by a saw or file.

2 It’s also important to tidy up the rails after soldering power feeds or if installing copperclad sleepers, especially at baseboard joints. A rub with successive grades of abrasive pads will remove any excess solder and flux residues.

3 Track rubbers are available from many manufacturers, consisting of various grades of abrasive material. They work quickly and effectively, but many are prone to leaving behind plenty of debris (see Step 6).

4 Track rubbers are great for removing paint from the rail heads, particularly after weathering. As well as the horizontal rail head surfaces, keeping the inside edges of the rails clear maximises the conductive surface area.

5 Finer sanding pads, of medium and fine grades, are useful for treating point blades and their contact surfaces. Again, working on the upper, inner faces of the rails provides a greater conductive area for the wheels.

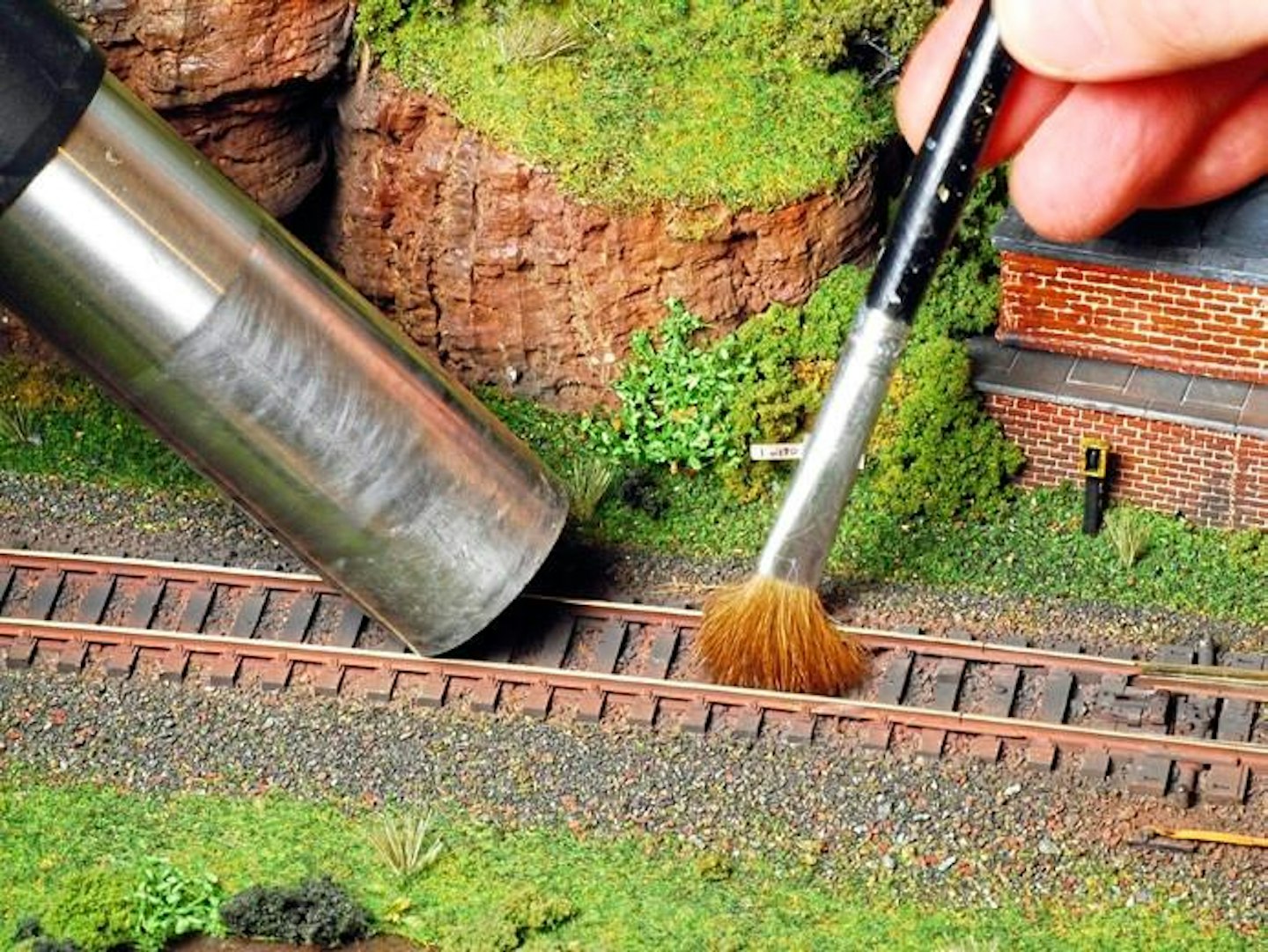

6 It’s important to remove debris from the track rubber, lest it be picked up by wheels and deposited elsewhere. A soft brush can sweep debris away from rails or, for best results, brush it towards the nozzle of a vacuum cleaner.

Mobile Rail Cleaners

Many of our layouts feature areas that aren’t so easy to reach by hand, such as within tunnels or hidden sidings. Fixing a track rubber to a length of wood may help to a degree, but a mobile cleaner offers a labour-saving and far-reaching solution.

Dapol’s motorised track-cleaning car offers an innovative option, with a spinning abrasive pad to clear away dirt from the rail heads, plus a vacuum to suck up dust and debris into an internal storage bin. It can also be fitted with cloth pads which can be loaded with a cleaning fluid (also offered by Dapol) to condition the rails. Although it’s not self-propelled, it does take power from the rails and can be hauled around the layout at regular intervals. Numerous special liveries have been offered over the years, including this exclusive Model Rail version from the late 2000s.

Web: www.dapol.co.uk

STEP BY STEP

1 Rails may appear clean, but close inspection may reveal a build-up of dirt. Dust is an ever-present hazard and nickel silver rail is naturally prone to tarnishing, especially in damp conditions, so regular cleaning is a must.

2 While an abrasive track rubber may be best for stubborn deposits, a cleaning fluid is ideal for more regular use. Dampen a scrap of cotton fabric (from an old T-shirt) with cleaning fluid and gently rub it over the tops of the rails.

3 You’ll be surprised by how much dirt is absorbed by the fabric – these rails appeared clean beforehand. Repeat the process, using a cotton swab to reach into awkward areas. Take care when working around delicate structures.

4 Allow a few minutes for the cleaner to dry on the rails before wiping with a clean cloth to remove any remaining dirt or residue. The Geoscenics cleaning fluid is alcohol-based and evaporates quickly.

5 The same fluid is also ideal for cleaning wheels of locomotives and rolling stock – an equally important task. Dip a cotton swab into the fluid and wipe over the wheel treads, moving to a clean swab when the tip becomes dirty.

Other, cheaper mobile cleaners are also available, in the form of adapted wagons, mostly from European manufacturers, although Gaugemaster has commissioned several anglicised versions over the years. This tank wagon is from the Lima range (Hornby International) and features a floating cloth pad between the axles, plus a healthy amount of weight to help keep the pad in contact with the rails while the wagon is in motion.

Soaking the pad with a suitable cleaning fluid allows the pad to clean and condition the rails as the wagon is hauled around the layout.

A quick repaint into a more convincing livery helped this track-cleaning wagon look more at home on a UK layout. Running this fictional de-icing train as part of the layout’s regular operations helps minimise the build-up of dirt on the rails.