To keep your precious models running in tip-top form, regular servicing is required. GEORGE DENT explains the ‘do’s and don’ts’ of lubrication.

Like any machine, a model locomotive must be properly lubricated to avoid unnecessary wear and tear. Although models are well lubricated during assembly, prolonged use may lead to a degrading of the oils, while long-term storage may see the lubricants dry out completely.

Moreover, dirt and other contaminants are readily picked up from dusty layouts or trainsets, being captured and retained by sticky lubricants, so an occasional ‘spring clean’ of mechanisms is a good idea. This may only take a few minutes, with a dusting and a few drops of light oil to the axles all that’s required. Higher mileage models, however, may need a little extra TLC.

The design of the locomotive dictates how easily it can be serviced and modern models tend to keep the various gears and driveshafts protected from dirt ingress. Indeed, fitting protective covers to gear trains also helps to prevent the lubricants from leaking. In contrast, older RTR and most kit-built traction have all or part of the transmission exposed, meaning that regular cleaning and re-lubricating is essential.

Along with motors and gears, coupling rods and wheel bearings also benefit from a light oiling. Wherever possible, refer to the locomotive’s supplied instructions and follow the manufacturer’s recommended practice closely. If you don’t have the instructions, duplicates are freely available from manufacturers’ websites.

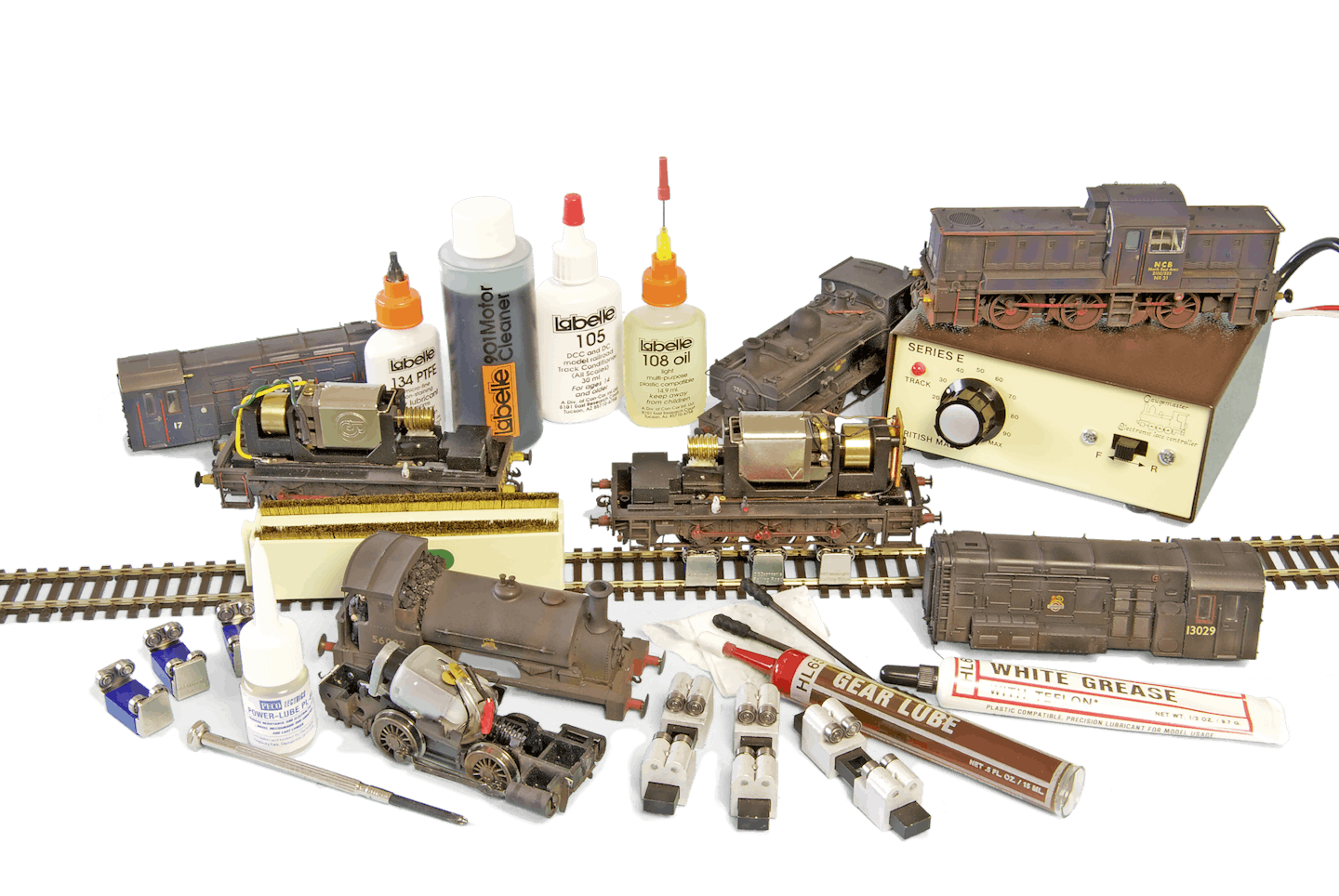

Choosing the right kind of oil is important - never use generic household oils - and they should be applied sparingly. There are plenty of options available, from RTR brands such as Dapol, Bachmann and Hornby, as well as Peco, Labelle and Woodland Scenics. Along with a light, thin oil, you’ll also need a thicker grease for gears. Electrically conductive lubricants are also useful for maintaining optimum performance.

‘ANY’ GAUGE

DIFFICULTY:

1 Screwdrivers

ESTIMATED TIME:

1 hour per loco

TOOLS NEEDED:

Model oil or grease, mini screwdrivers, tweezers, swabs

The first job is to clean away dust and debris with a soft dry brush. If dirt is trapped in oil or grease on the chassis, dip a brush in iso-propyl alcohol or a proprietary model cleaning fluid before working it over the affected areas and allow to dry.

Next, give all of the wheels a deep clean with a swab dipped in track cleaning fluid. Treat the treads and the rear faces if power collecting ‘wipers’ bear onto them. This Trix wheel cleaner is handy for treating powered wheelsets, especially when lubricated with a track cleaning fluid.

It’s worth consulting the instructions or service sheet provided with a locomotive. This is likely to recommend where and when to lubricate the various moving parts, as well as showing how to remove the bodyshell. Duplicates can be obtained from most manufacturers’ websites.

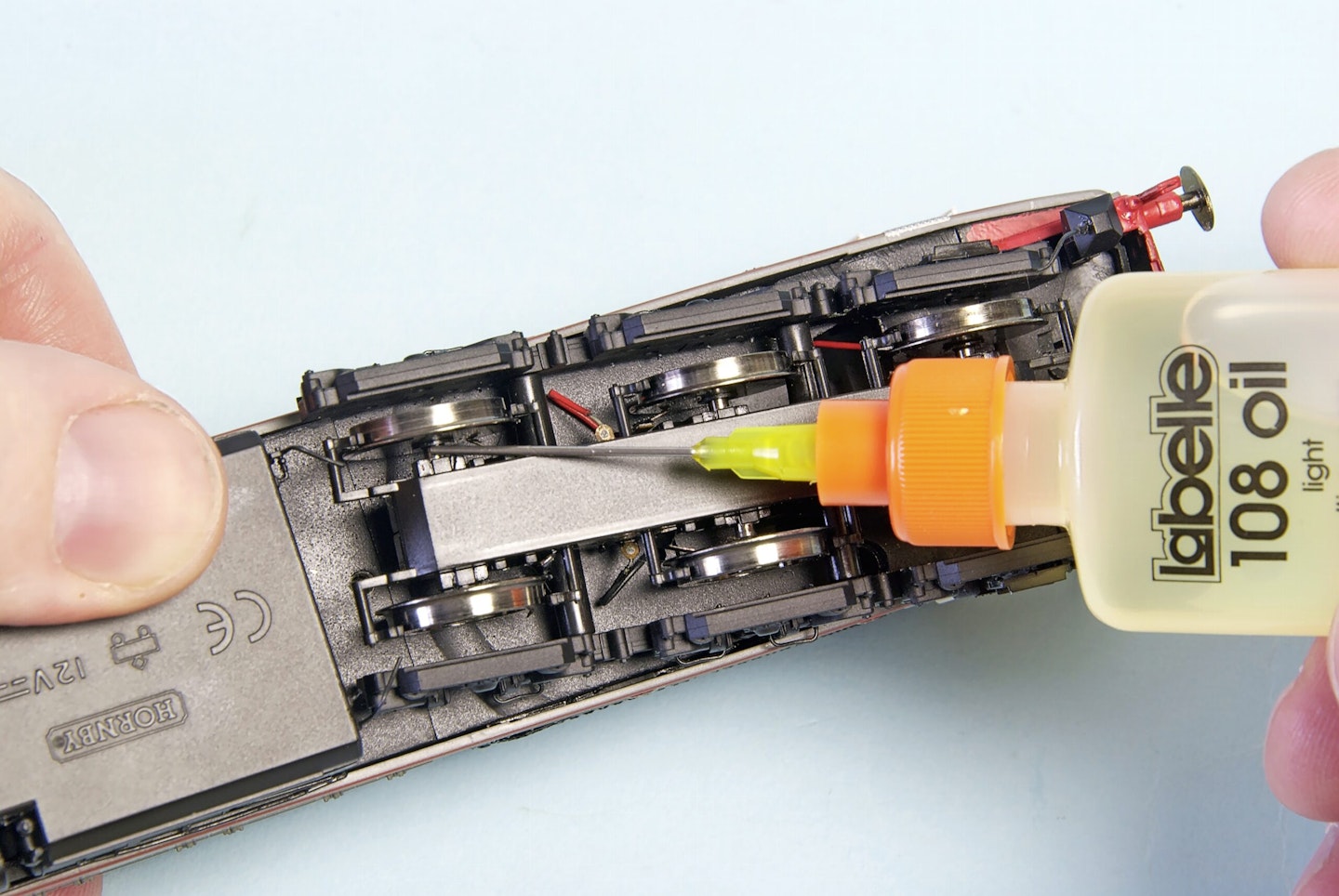

One of the easiest oiling points is the axle bearings of each powered axle. A single drop of light oil, such as Labelle 108, onto each side of all axles will suffice. The oil will penetrate into the bearing as the axle turns.

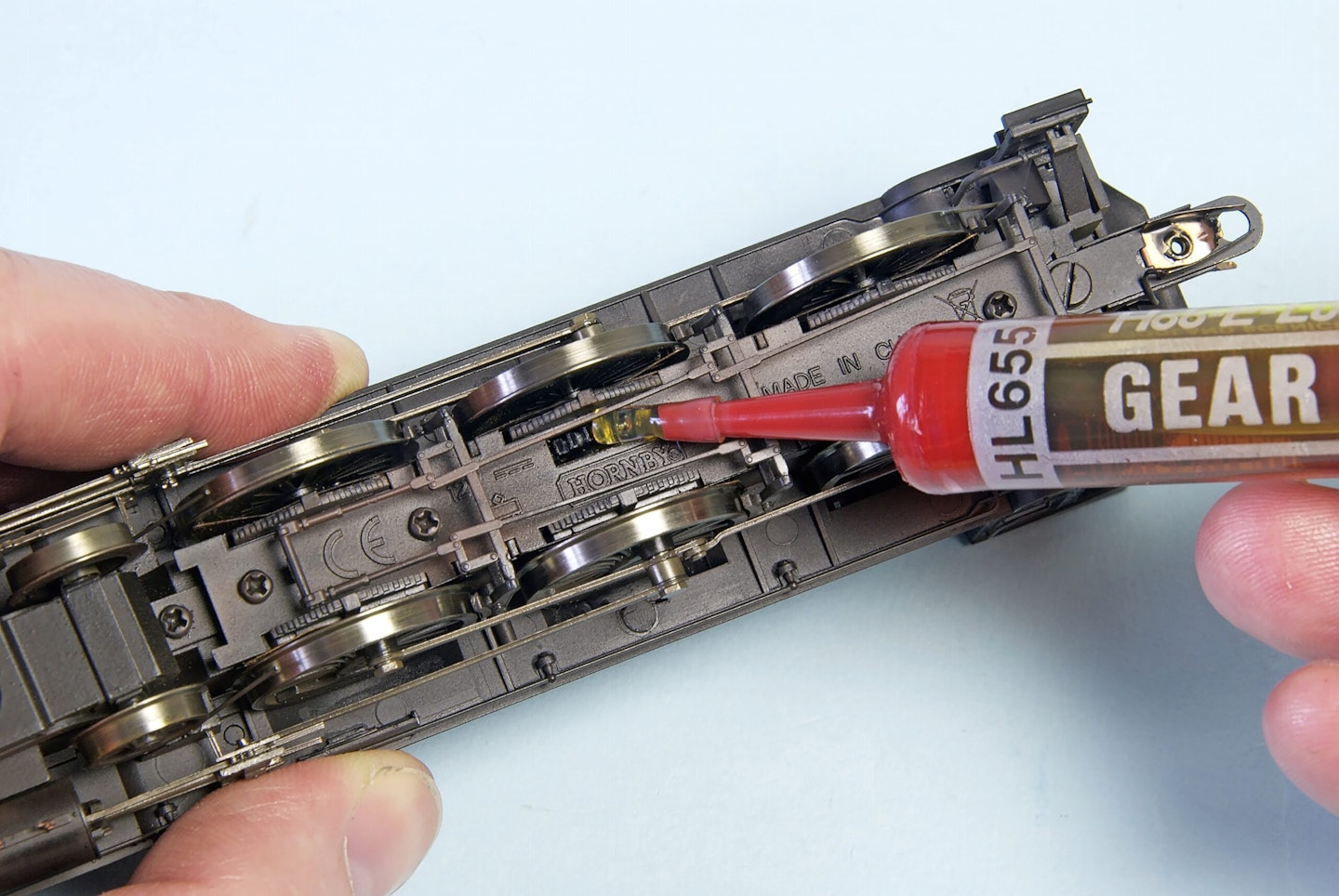

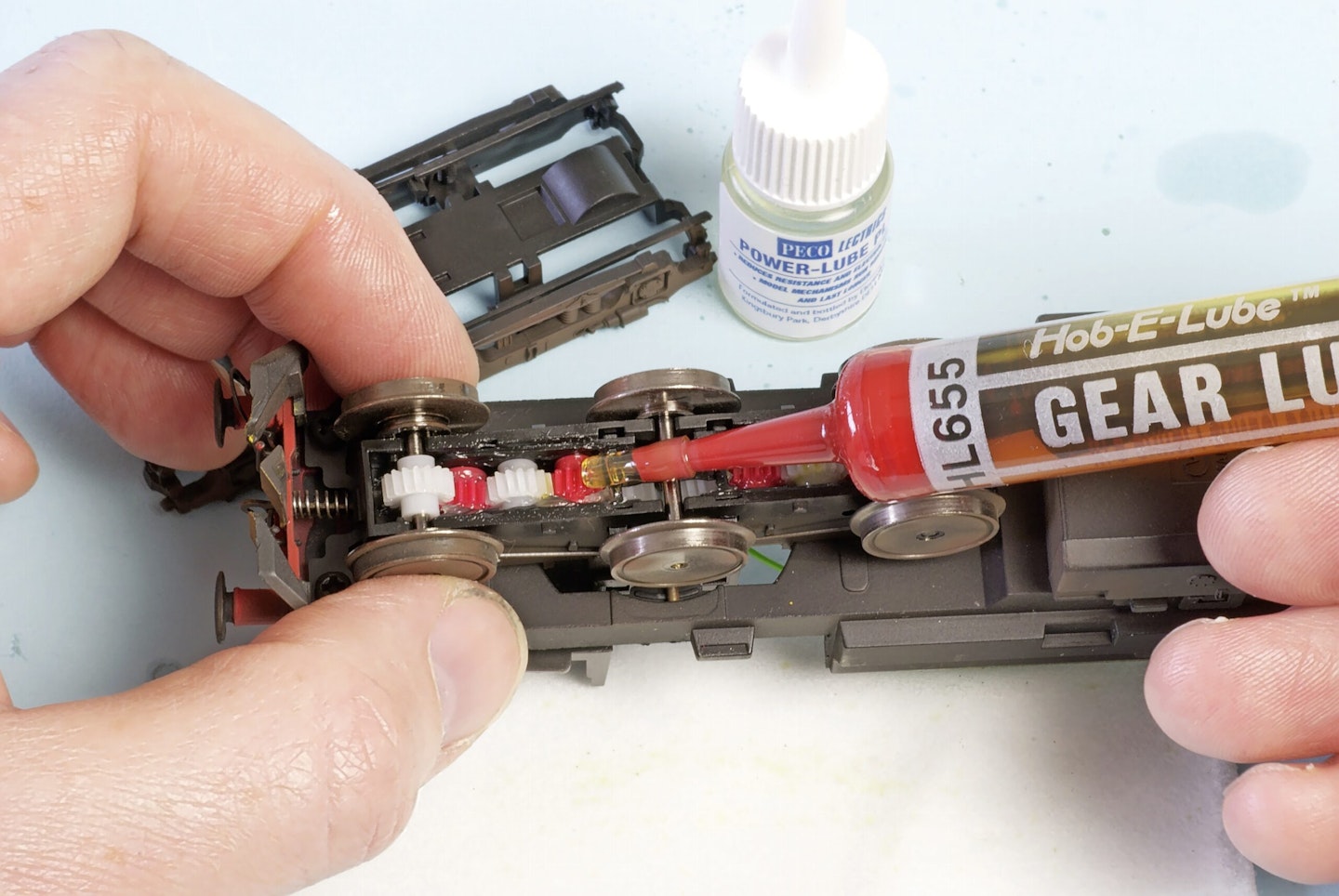

Models with exposed gears below the chassis are convenient for servicing but can attract dust and dirt. After cleaning, apply a small drop of a thicker lubricant such as Hob-e-Lube’s Gear Lube (available from Bachmann stockists).

A single drop of light oil (such as Labelle 108) to each crank pin and coupling rod joint will reduce friction and promote smoother running. Put a drop on the slide bars and piston rods too, to ease them in their passage. This is where a needlepoint applicator really helps.

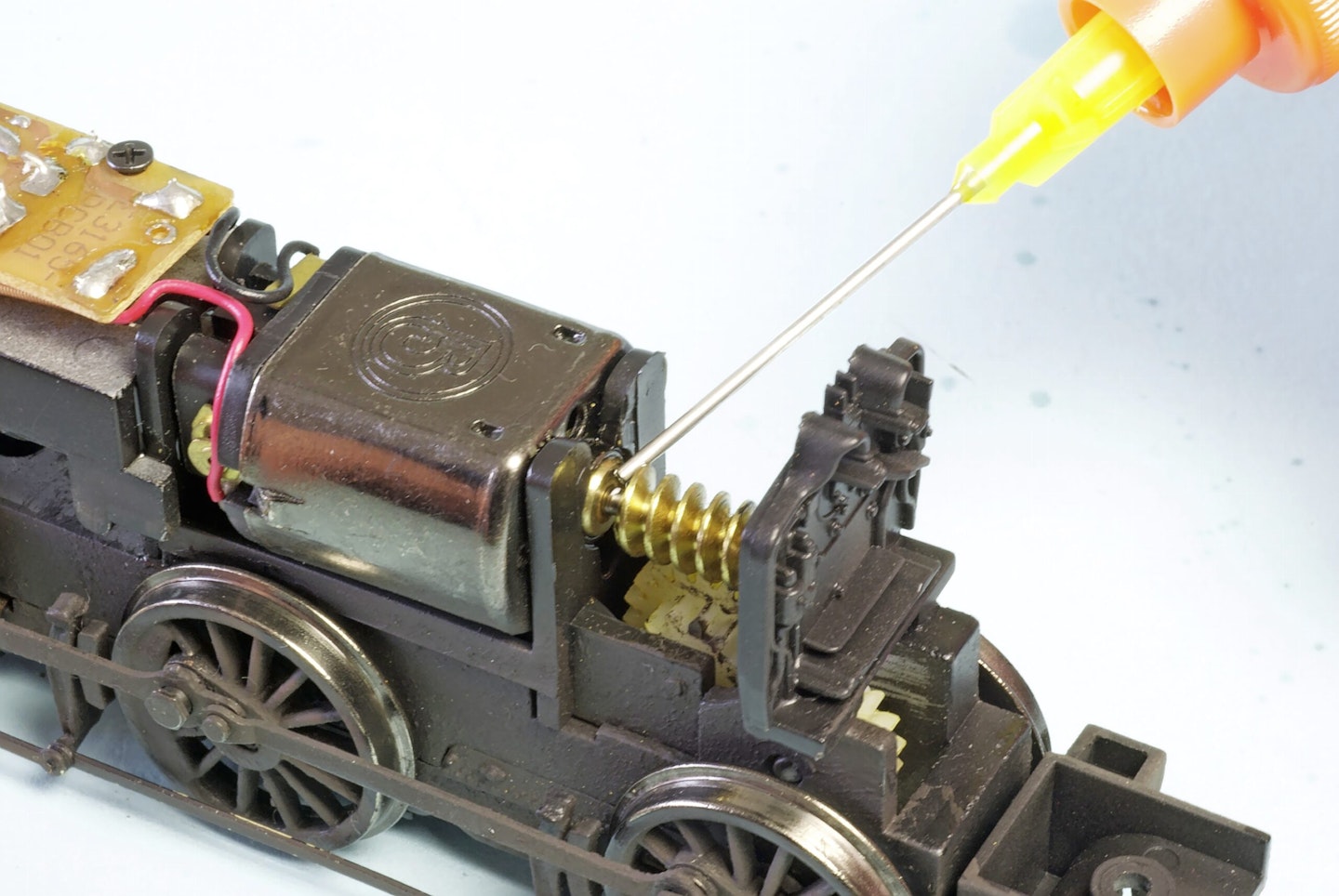

A drop of light oil onto the motor armature shaft bearings - at each end of the motor - will keep the motor running freely. Use the oil sparingly, to prevent ingress into the motor itself. The oil will penetrate the bearing naturally.

Check that all gears are free from dirt or dust fibres. A small spreading of the Gear Lube on the worm drive will be sufficient. As the motor is run, the lubricant will be spread throughout the gearbox, leaving a thin film on the working surfaces.

Where long gear trains are employed, especially in diesel and electric outline models, a few extra drops of Gear Lube can be distributed, after removing the access panels. These commonly unclip from the base of the bogie frames.

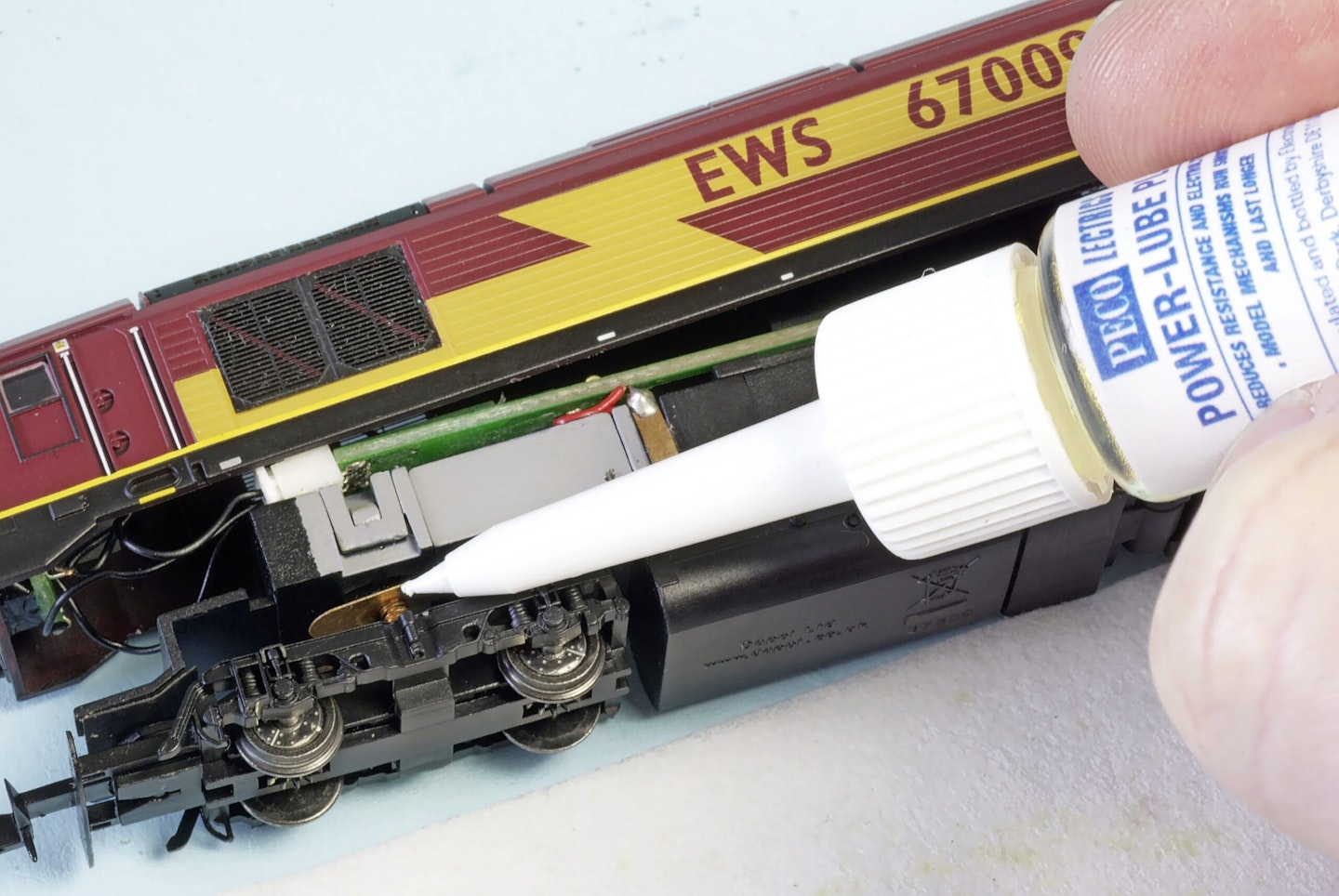

Any electrical contacts, such as these beneath a Dapol Class 67, can be cleaned and lubricated at the same time with a drop of Peco Power-Lube. It’s worth re-cleaning the wheels before test-running the locomotive, to remove any errant traces of oil or grease.

TOP TOOL

A rolling road allows locomotives to be test-run on the workbench or an accessible part of the layout. This makes it easier for us to identify any faults and make adjustments. This set of individual axle cradles is from the DCCconcepts range and they can be adjusted to suit various gauges and take their power from the direct from a layout’s rails.

Availability

DCCconcepts

Tel. 01729 821080

Web: www.dccconcepts.com

USEFUL SOURCES

Labelle oils and cleaning fluids

Availability:

Golden Valley Hobbies

Tel. 01981 241237

Web: www.goldenvalleyhobbies.com